We had taken the sail down, but it was far too windy to continue with that job, so we decided to tackle a little job inside the boat and that was our fixing our radio mic. The cable that we ordered had come in, so I was really happy. Mean while Prudence had applied some magic and we had acquired a new to us radio mic from one of our followers. As a solution this is perfect, but we decided that we would still fix the old radio mic because it would mean that we had a workable spare.

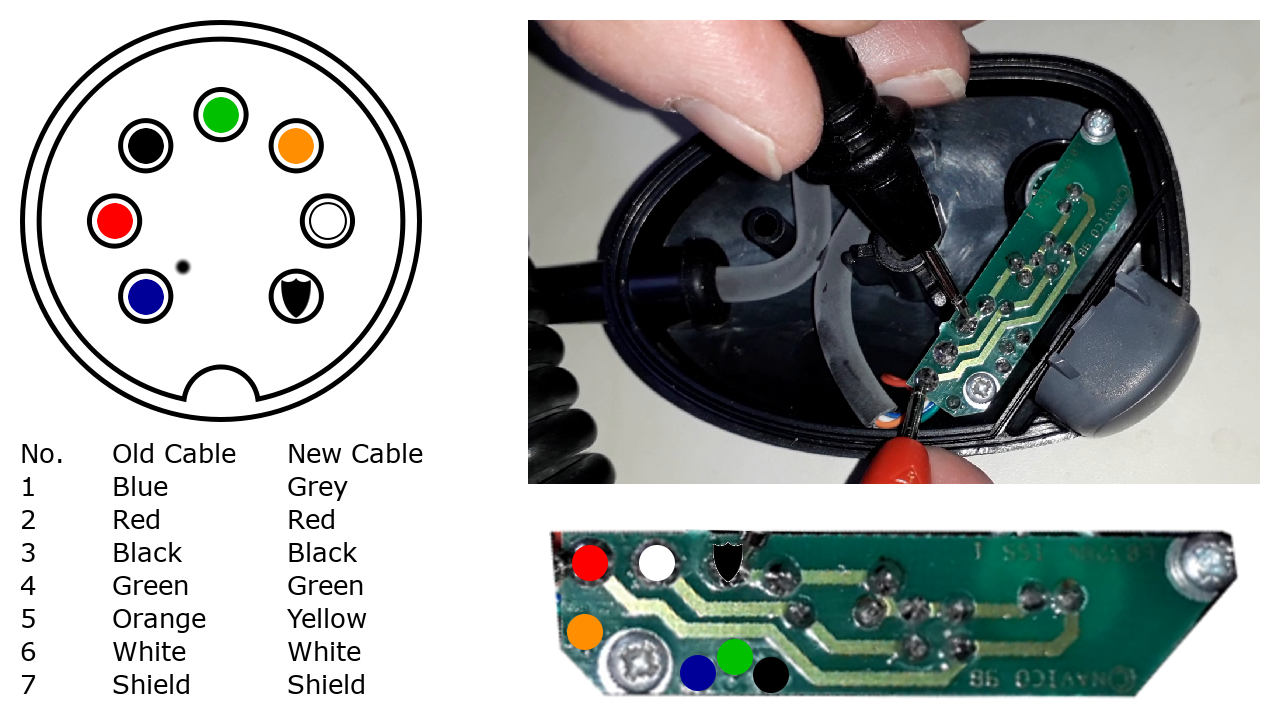

Fixing the radio microphone

- Forceps - They were actually long tweezes bit in the end we used ordinary tweezes as we could not find our long pair when we did the job

- Multi meter - Used for checking the connections and tapping the cable out

- Soldering Iron

- Solder - Ours is from Maplin, but it still works

- Heat shrink - Various sizes, a long length to cover the main cable and some fine heat shrink for covering the individual wires

- Solder sucker - Removes solder

- Magnifying glass - Used to inspect the new solder connections for dry joints

Initially I was short of a solder sucker and a long length of heat shrink, so I took the opportunity to review our tools. Once I had purchased a solder sucker and some more heat shrink, we used the Multi meter to work out which coloured wire went from the small circuit board to the connector, but before I did that I made sure that none of the wires were connected through the circuit board.